FooCAD Source Code/**

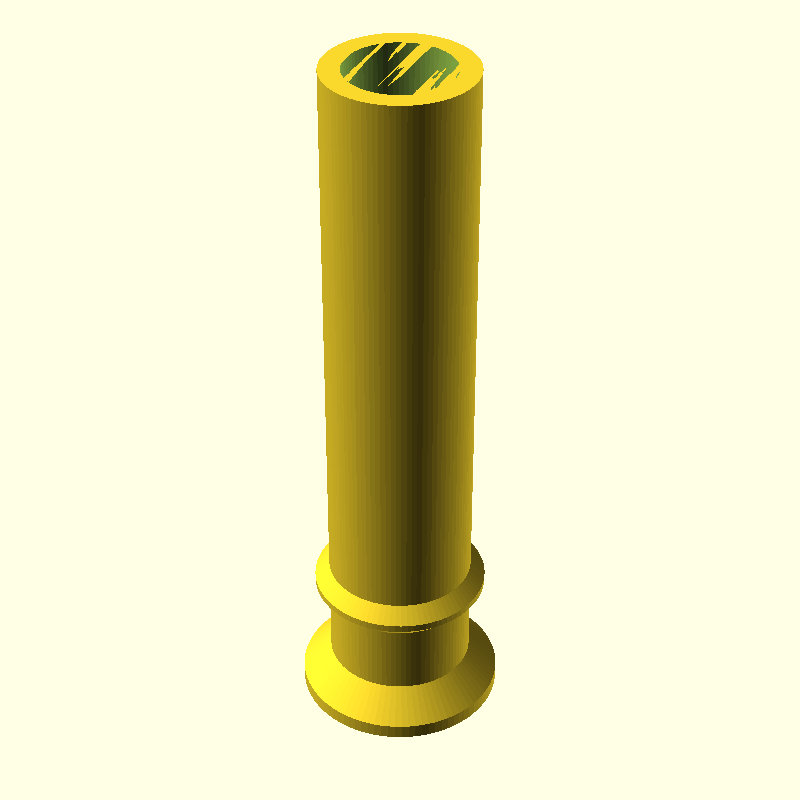

For Genius and Artillery X1/2 printers.

Adds 2 rollers, so that any filament spools can be placed on the printer

without having to adjust the width to match the spool's width.

You need 2 rollers per printer.

Print Notes

I added ears with ribs, radius 14, as this is very tall, with a small footprint.

*/

class GeniusSpoolRoller : AbstractModel() {

@Custom(about="Length of the middle section of the roller" )

var maxWidth = 85 // The maximum width of your spools.

@Custom( about="Side of the chamfer at the ends of the roller" )

var chamfer = 4

@Custom( about="Diameter of the roller" )

var diameter = 20

@Custom (about = "Thickness of the wall" )

var thickness = 1.2

@Custom( about="Position of the lip, which stops the spool moving left/right too much")

var lipAt = 10

// My first print used 4mm, which is a bit too big!??

@Custom( about="The height of the lip" )

var lipChamfer = 2

@Custom( about="Diamter and depth of the holes to house the bearings" )

var bearing = Vector2(14.4, 18)

// A generous brim, is needed due to the height and small footprint.

// All perimeters - no infill

@Slice( brimWidth=20, perimeters=50 )

override fun build() : Shape3d {

val circle = Circle( chamfer + diameter/2 )

val main = ExtrusionBuilder().apply {

crossSection( circle )

forward(2)

crossSection()

forward( chamfer )

crossSection( -chamfer )

forward( lipAt )

crossSection()

forward( lipChamfer )

crossSection( lipChamfer )

forward(1)

crossSection()

forward( lipChamfer )

crossSection( -lipChamfer )

forward( maxWidth - lipChamfer * 2 - 1 - lipAt + chamfer + 2 )

crossSection()

}.build()

val insideRadius = diameter/2 - thickness

val diff = insideRadius - bearing.x/2

val hole = ExtrusionBuilder().apply {

crossSection( Circle( bearing.x/2 ) )

forward( bearing.y )

crossSection()

forward( diff )

crossSection( Circle(insideRadius ) )

forward( main.top - diff * 2 - bearing.y * 2 )

crossSection()

forward(diff)

crossSection( Circle( bearing.x/2 ) )

forward(bearing.y )

crossSection()

}.build()

// Even with Ears, I've still had failures when the top had a chamfer similar to be bottom

// return main + ears( main, 19 ).ribs( 0.8, 2 ).ribsMargin(0.5) - hole

return main - hole

}

/**

The part got knocked over by the hot-end when printing the top chamfer,

So this piece is to be glued to the main part. An annoying bodge, but it works!

*/

@Piece

fun extraChamfer() : Shape3d {

val circle = Circle( chamfer + diameter/2 )

val main = ExtrusionBuilder().apply {

crossSection( circle )

forward(2)

crossSection()

forward(chamfer)

crossSection(-chamfer)

}.build()

val hole = Cylinder( 100, diameter/2 + 0.1 ).center()

return main - hole

}

}